Michigan Micro Mote (M3) makes history as the world’s smallest computer

Enlarge

Enlarge

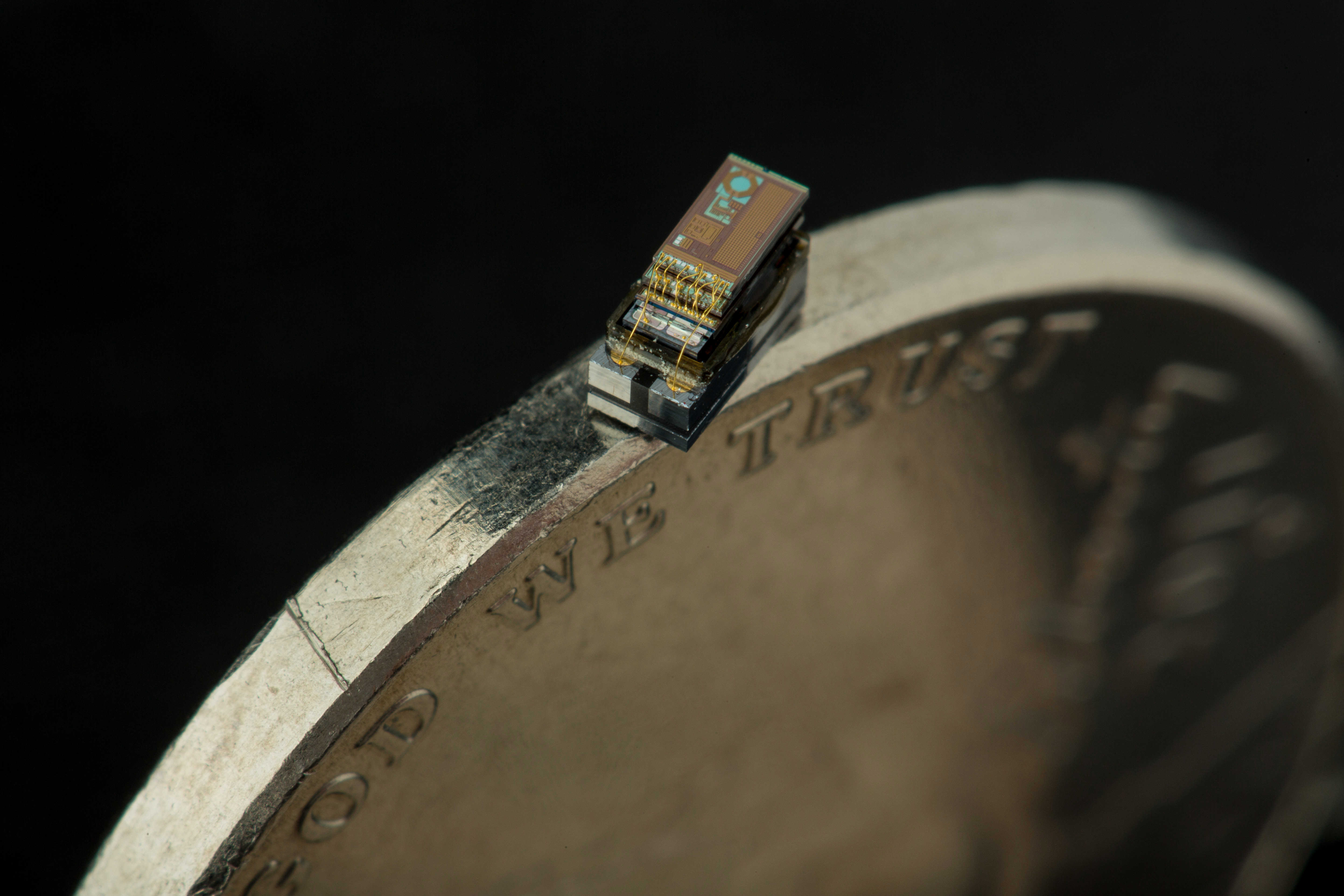

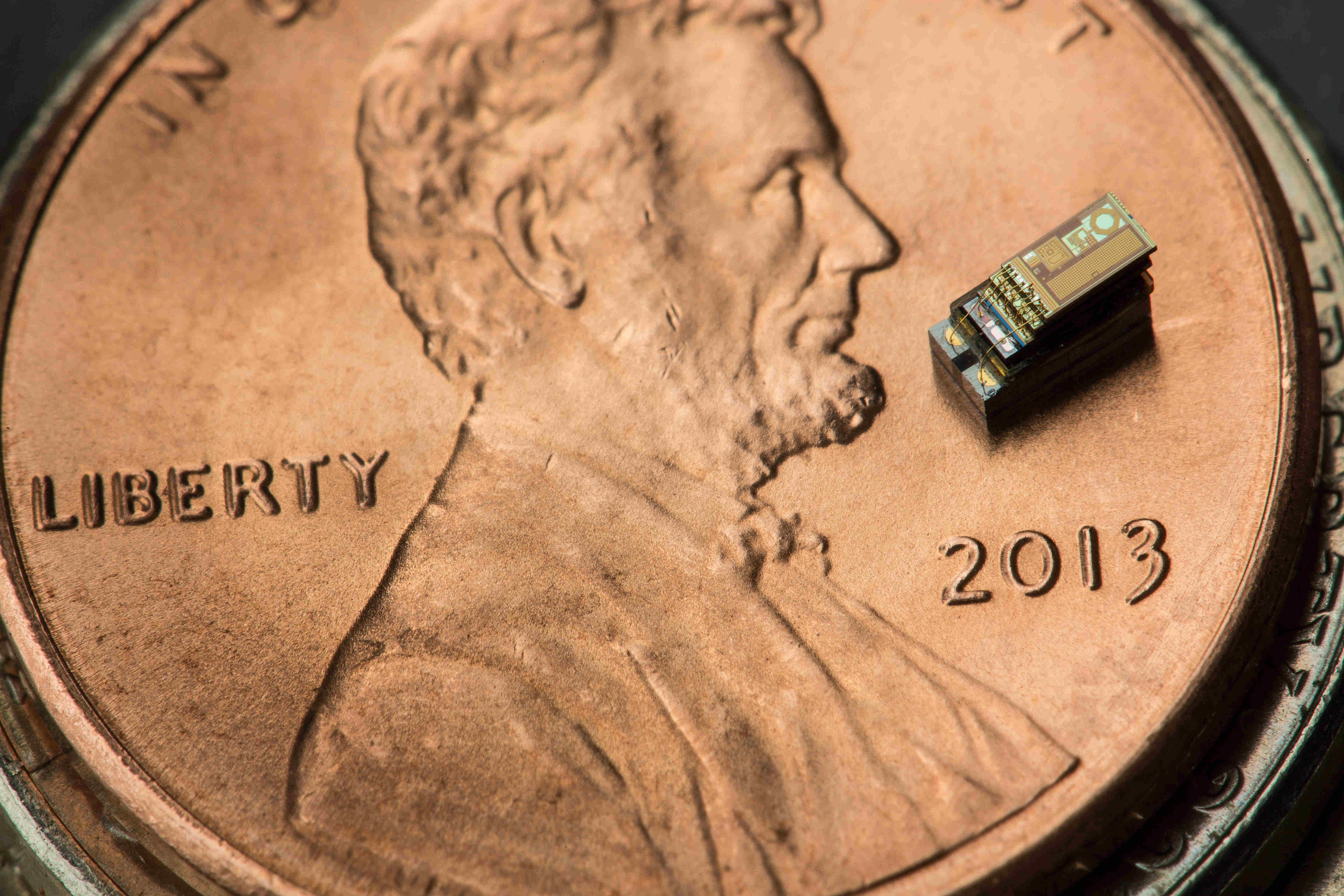

Michigan Micro Mote (M3), the world’s smallest computer, has taken its place among other revolutionary accomplishments in the history of computing at the Computer History Museum in Mountain View, CA. Measuring in at less than a half a centimeter, it didn’t take a truck to transport the computers early in 2015 from their home in Ann Arbor, MI. In fact, nearly 150 of these computers fit inside a single thimble.

Read what the museum says about their newest exhibit.

The M3 is a fully autonomous computing system that acts as a smart sensing system. It is the achievement of Michigan faculty members David Blaauw, Dennis Sylvester, David Wentzloff, Prabal Dutta and several key graduate students over the years, some of whom have already founded companies to exploit key aspects of the technology. These devices are helping usher in the era of the Internet of Things (IoT), where people are connected to things and other people through the cloud.

In the IoT world, size and power are everything. The computers have to be small in order to sense the world around us without being intrusive, and they have to run on extremely low power to match their size.

The Michigan Micro Mote constitutes the first complete, operational computer system measuring as small as two millimeters across. “To be “complete,” a computer system must have an input of data, the ability to process that data – meaning process and store it, make decisions about what to do next – and ultimately, the ability to output the data.” Prof. Blaauw explained. “The sensors are the input and the radios are the output. The other key to being a complete computer is the ability to supply its own power.”

The Michigan Micro Mote contains solar cells that power the battery with ambient light, including indoor rooms with no natural sunlight, allowing the computers to run perpetually.

Download these and additional photos on Flickr

This line of “smart dust” devices includes computers equipped with imagers (with motion detection), temperature sensors, and pressure sensors. They are the culmination of work initiated by Blaauw and Sylvester on very low-power processing for millimeter-scale systems.

An Astonishing Lack of Power

A key breakthrough in the size/power matchup came with the Phoenix processor in 2008. The Phoenix processor is miniscule at 915 x 915µm2, and boasts ultra-low operating voltage and a unique standby mode that results in an average power consumption of only 500pW. (Consider that 1pW is the average power consumption of a single human cell.)

Enlarge

Enlarge

Blaauw explained why Phoenix’s extreme energy efficiency is so important: “As you shrink down in size, the percentage of the system tends to be dominated by the battery. It’s actually not hard to make chips small, but it is hard to make them low power. We could have very small chips, but we’d still end up with really large batteries.”

With the M3, engineers at Michigan are the first to accomplish energy neutrality via indoor energy harvesting in a wireless system of its size. With a 1mm2 solar cell producing 20nW, the device can harvest enough energy under ambient light to run perpetually. The device’s standby power consumption is 2nA. That’s about a million times less power than the average mobile phone consumes while on standby, or the comparative difference between the thickness of a sheet of paper and the length of a football field.

M3 Versatility

There are currently three different systems in the M3 family, focusing on several different applications: sensing temperature, pressure, and taking images.

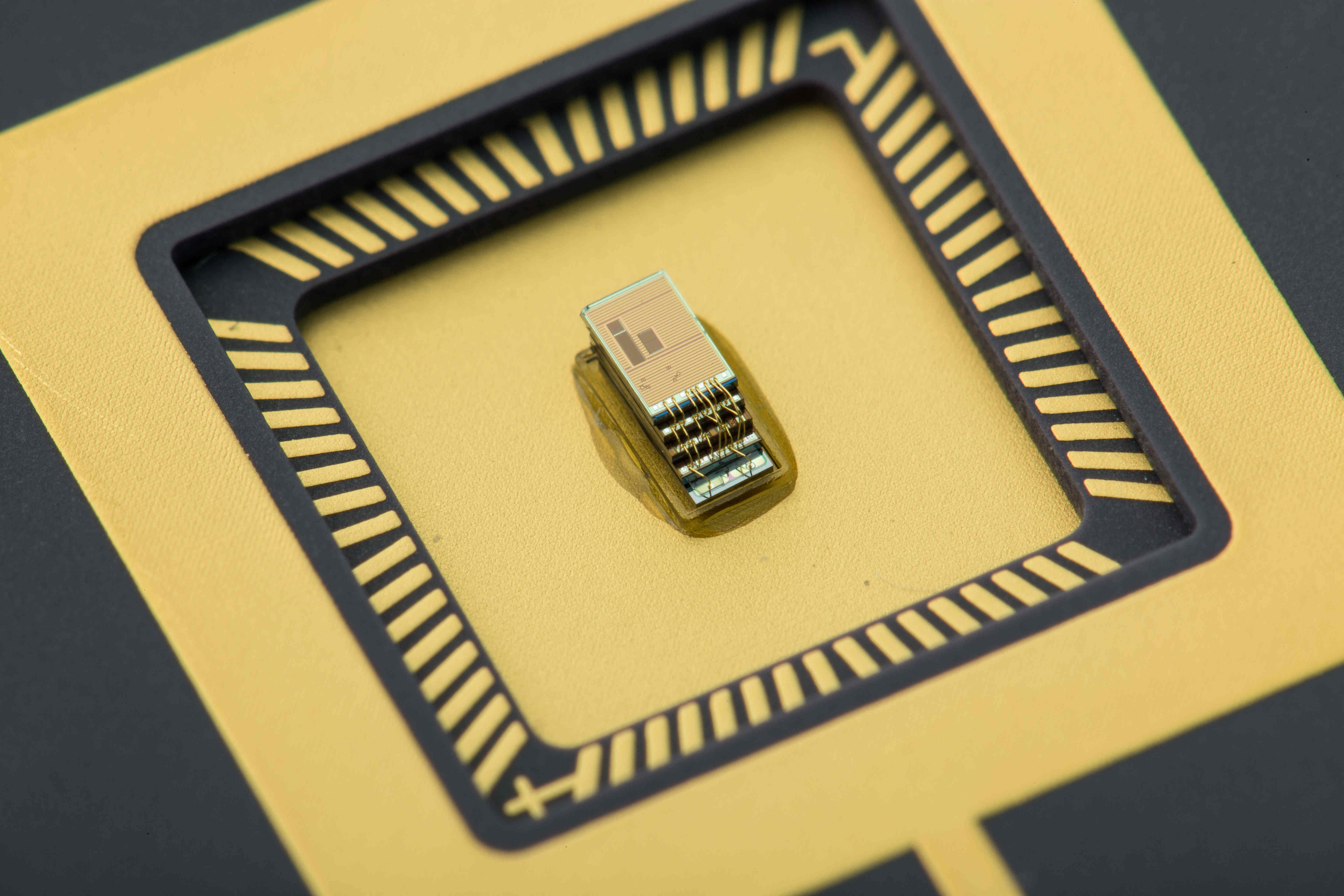

The Michigan Micro Mote is built in stacked layers which are able to communicate through a specially-designed universal interface protocol called MBus. Each M3 computer contains the following layers:

- solar cell and optical communication photo cell

- harvester control electronics layer

- radio layer

- sensor interface layer (temp sensor and capacitive interface electronics)

- layer with capacitors for stabilizing the power supplies (“decap” layer)

- processor + memory + power regulation layer

- battery

- optional layer for pressure sensor, imager, etc.

Enlarge

Enlarge

By simply exchanging one layer with another, a new sensing system is achieved. This design methodology greatly reduces the cost of manufacturing.

The current pinnacle of the project is an imaging system that packs visual imaging, ultra-low power motion detection, wireless communications, battery, power management, solar harvesting, processor and memory into a package measuring a mere 2 x 4 x 4mm3.

Wireless Communication

Currently, all of the M3 computers can collect and transmit data as far as 2 meters, about the width of a cubicle. At that range these computers can monitor a room for motion or anomalies in pressure and temperature, all while communicating that data to a base station.

The sensors activate on their own to take periodic measurements and then log that data until it is sent. Operating at extremely low power during the “sleep” time is one of the many keys to the success of this technology.

“Down the road we want these sensors to be able to talk to one another,” says Blaauw, “and we’re currently working to extend their range to about 20m.”

A stumbling block to extending the range of these devices is the antenna size and accompanying increase in power needed to communicate long distances. Prof. Wentzloff is leading the effort to increase the ability of the M3 to communicate over longer distances.

Enlarge

Enlarge

In recent work, Wentzloff and his group achieved wireless communication from the M3 with temperature sensor to a base station up to 7m away. The complete sensor node is energy autonomous with a 2mm, 2μAh battery and an integrated solar cell.

M3 Applications

The first generation of Phoenix-based sensors were developed for implantable medical devices. The sensor system included a MEMS pressure sensor that could be deployed to monitor intraocular pressure in glaucoma patients and intracranial pressure in trauma victims. The latter application would replace the current method of inserting a wire into the skull, which leaves the patient vulnerable to infection.

Researchers and companies around the world are figuring out new ways to use these mini-computer sensing devices every day. The Michigan team is aiding in the process by sending the M3 to interested researchers, as well as responding to the most intriguing projects that come their way. Michigan has been inundated with requests to use these devices in applications from monitoring concrete and oil wells to researching the behavior of snails.

Enlarge

Enlarge

One key application for this line of smart sensors lies in personal security and information. Numerous specks of technology could be discretely placed to invisibly monitor a home, business, or personal device.

“We found that a lot of people were very interested in these devices, and that’s why we went with the modular or stacked approach.” Blaauw explained. “It’s the key aspect of our design. If you need a different sensing modality you take out one sensor and replace it with another – like mix and match tinker toys.”

Tech Transfer

The future of smart dust is being realized by a number of startups coming out of the M3 group.

Enlarge

Enlarge

The first to appear, Ambiq Micro (2010), develops energy efficient microcontrollers built around millimeter-scale chips. Ambiq, founded by Dr. Scott Hanson, Prof. David Blaauw and Prof. Dennis Sylvester, seeks a world of ubiquitous computing, and its tiny controllers are a step in that direction. Ambiq’s technology is an example of embedded intelligent sensors expanding the Internet of Things.

Enlarge

Enlarge

PsiKick was founded in 2012 by Prof. David Wentzloff, Prof. Benton Calhoun of the University of Virginia, and Brendan Richardson. PsiKick is commercializing their own line of ultra-low power systems-on-a-chip. Their systems are capable of harvesting energy from vibration, thermal gradients, solar, radiofrequency and piezo actuation. One of PsiKick’s first demonstrations was an EKG monitoring sensor powered by body heat.

Enlarge

Enlarge

CubeWorks was founded in 2013 by Michigan researchers Dr. ZhiYoong Foo, Dr. Gyouho Kim, and Dr. Yoonmyung Lee; and faculty, David Blaauw, David Wentzloff, Dennis Sylvester, and Prabal Dutta. M3 itself is the core technology of this company. The goal of CubeWorks is to deliver a true “smart dust” to open up the next generation of computing paradigm, accelerating massive-scale realization of Internet of Things.

Enlarge

Enlarge

Movellus was founded in 2014 by former PhD students Muhammed Faisal and Jeffrey Fredenburg, along with Associate Professor David Wentzloff. The team designed a digital clock generator that can replace the analog clock generator on microprocessors. This improves battery life of the component, reduces its size, and reduces the time required for design. With microprocessors now pervasive in society, in refrigerators, thermostats, televisions, and toys, Movellus’ design has a broad impact for our future living in the Internet of Things.

The Future

The door has been opened to a completely new class of computing with seemingly limitless applications. Worldwide exploration of this research is being aided by the dissemination of hundreds of Michigan Micro Motes for trials in innovative applications. In the meantime, the Michigan team continues to redefine computer technology ahead of the IoT curve as they collaborate with industry, the Kellogg Eye Center, the U-M Medical School, and colleagues here at Michigan and around the world.

What’s New

M3 In Action: These Injectable Computers Can Broadcast from Inside the Body (2016)

Enlarge

Enlarge

Computer History Museum Games

Enlarge

Enlarge

If you are standing in front of the exhibit at the Computer History Museum in Mountain View, CA, here are your answers:

1. There are 52 computers in the thimble (we estimate it would take close to 150 to fill the thimble)

2. One of the hidden M3 computers is on the punch card.

Enlarge

Enlarge

Additional Information

2011 – Integrating Circuits, Sensing, and Software to Realize the Cubic-mm Computing Class, EECS Department

2011 – Toward computers that fit on a pen tip: New technologies usher in the millimeter-scale computing era, U-M Press Release

2010 – Tiny solar-powered sensor runs almost forever, NBC

2010 – Millimeter-scale, energy-harvesting sensor system developed, U-M Press Release

Key Papers

MBus: an ultra-low power interconnect bus for next generation nanopower systems, by P. Pannuto, Y. Lee, Y. Kuo, Z. Foo, B. Kempke, G. Kim, R. Dreslinski, D. Blaauw, and P. Dutta. 42nd International Symposium on Computer Architecture (ISCA). Named IEEE Micro Top Pick from the 2015 Computer Architecture Conferences.

MBus: A 17.5 pJ/bit/chip Portable Interconnect Bus for Millimeter-Scale Sensor Systems with 8 nW Standby Power, by Y. Kuo, P. Pannuto, G. Kim, Z. Foo, I. Lee, B. Kempke, P. Dutta, D. Blaauw, and Y. Lee, 2014 IEEE Custom Integrated Circuits Conference, September 2014.

A fully integrated 71nW CMOS temperature sensor for low power wireless sensor nodes, by S. Jeong, Z. Foo, Y. Lee, J-Y. Sim, D. Blaauw, and D. Sylvester, IEEE Journal of Solid-State Circuits (JSSC), August 2014.

A Millimeter-Scale Wireless Imaging System with Continuous Motion Detection and Energy Harvesting, by G. Kim, Y. Lee, Z. Foo, P. Pannuto, Y. Kuo, B. Kempke, M. Ghaed, S. Bang, I. Lee, Y. Kim, S. Jeong, P. Dutta, D. Sylvester, and D. Blaauw, 2014 Symposium on VLSI Circuits, June 2014.

Circuits for a cubic millimeter energy-autonomous wireless intraocular pressure monitor, by M.H. Ghaed, G. Chen, R-ul. Haque, M. Wieckowski, Y. Kim, G. Kim, Y. Lee, I. Lee, D. Fick, D. Kim, M. Seok, K.D. Wise, D. Blaauw, and D. Sylvester, IEEE Transactions on Circuits and Systems I, December 2013.

A Sub-nW Multi-stage Temperature Compensated Timer for Ultra-Low-Power Sensor Nodes, by Y. Lee, B. Ghiridar, Z. Foo, D. Sylvester, and D. Blaauw, IEEE Journal of Solid-State Circuits (JSSC), October 2013.

A millimeter-scale energy-autonomous sensor system with stacked battery and solar cells, by M. Fojtik, D. Kim, G. Chen, Y-S. Lin, D. Fick, J. Park, M. Seok, M-T. Chen, Z. Foo, D. Blaauw, and D. Sylvester, IEEE Journal of Solid-State Circuits, March 2013.

A Modular 1 mm Die-Stacked Sensing Platform With Low Power I C Inter-Die Communication and Multi-Modal Energy Harvesting, by Y. Lee, S. Bang, I. Lee, Y. Kim, G. Kim, M. Ghaed, P. Pannuto, P. Dutta, D. Sylvester, and D. Blaauw, IEEE Journal of Solid-State Circuits, January 2013.

A 60GHz Antenna-Referenced Frequency-Locked Loop in 0.13μm CMOS for Wireless Sensor Networks, by K.-K. Huang and D. Wentzloff, 2011 IEEE International Solid-State Circuits Conference (ISSCC).

A cubic-millimeter energy-autonomous wireless intraocular pressure monitor, by G. Chen, H. Ghaed, R. Haque, M. Wieckowski, Y. Kim, G. Kim, D. Fick, D. Kim, M. Seok, K. Wise, D. Blaauw, and D. Sylvester, 2011 IEEE International Solid-State Circuits Conference (ISSCC).

Millimeter-scale nearly perpetual sensor system with stacked battery and solar cells, by G. Chen, M. Fojtik, D. Kim, D. Fick, J. Park, M. Seok, M. Chen, Z. Foo, D. Sylvester, and D. Blaauw, 2010 IEEE International Solid-State Circuits Conference (ISSCC).

A low voltage processor for sensing applications with picowatt standby mode,” by S. Hanson, M. Seok, Y-S. Lin, Z. Foo, D. Kim, Y. Lee, N. Liu, D. Sylvester, and D. Blaauw, IEEE Journal of Solid-State Circuits, April 2009.

Related Videos

———————

———————

In the Media

Tiny snail computers

Michigan Radio talks about innovative technology that came out of ECE and EEB to help figure out what’s killing tiny snails.How Do You Solve an Extinction Mystery? Put a Tiny Computer on a Snail.

The New York Times features the Michigan Micro Mote and how it helped solve a mass extinction snail survivor mystery.World's smallest computer helps solve mystery of snail species survival

This partnership between biologists and engineers yields scientific insights into a surviving species of Tahitian tree snails, while also proving the viability for very small animal studies using the Michigan Micro Mote.Teeny-Tiny Bluetooth Transmitter Runs on Less Than 1 Milliwatt

Bluetooth low-energy data packets can now be sent by millimeter-size IoT motes

MENU

MENU